E-Michigan Gear, ikhwalithi yinto eza kuqala kithi. Ngesitifiketi sethu se-ISO 9001, isistimu yokuphatha ikhwalithi ye-IATF16949 kanye nesitifiketi se-ISO 14001 sohlelo lwezemvelo, Sithatha ukulawulwa kwekhwalithi ngokungathi sína futhi silandela imihlahlandlela eqinile namazinga ukuze siqinisekise ukuthi yonke imikhiqizo/isevisi esiyinikezayo ihlangabezana noma idlula lokho okulindelwe ngamakhasimende ethu.

Sizohlinzeka ngokusekelwa okuphelele kulo lonke ukwakhiwa komkhiqizo, ukuhlolwa kwe-prototype, ukukhiqiza kanye nenqubo yokuthengisa ngemva kokuthengisa. Thembela kulwazi nolwazi lwethimba lethu ukuze unikeze isevisi esheshayo, ethembekile nesezingeni lokuqala.

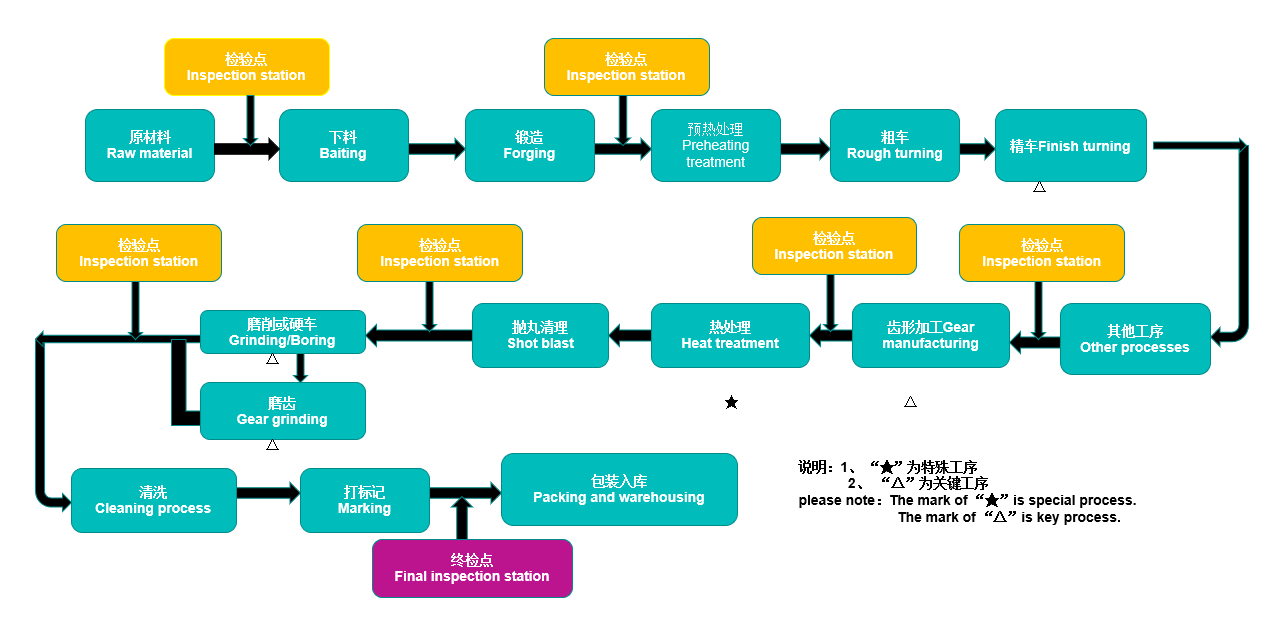

Inqubo Yokulawula Ikhwalithi

Ukubuyekezwa Kwedizayini

Lokhu kuhilela ukuhlola idizayini yegiya ukuze kutholakale ukunemba nokuhambisana nezindinganiso zobunjiniyela.

1. Isofthiwe ye-CAD:Isofthiwe ye-Computer-aid design (CAD) efana ne-SolidWorks, i-AutoCAD, ne-Inventor ingasetshenziswa ukudala nokuhlaziya izinhlobo ze-3D zamagiya. Ivumela ukwakheka okunembile nokuhlaziywa kwemingcele yokusebenza kwegiya.

2. Isofthiwe yokuklama igiya:njenge-KISSsoft, MDESIGN, ne-AGMA GearCalc engasetshenziswa ukuhlaziya imiklamo yegiya, ukubala amapharamitha adingekayo, futhi uqinisekise imiklamo.

3. Isofthiwe ye-Finite element analysis (FEA):Isoftware ye-FEA efana ne-ANSYS, ABAQUS, ne-Nastran ingasetshenziswa ukwenza ukucindezeleka nokuhlaziywa komthwalo kumagiya nezingxenye zawo. Leli thuluzi lisiza ukuqinisekisa ukuthi idizayini yegiya ingakwazi ukumelana nemithwalo kanye nezingcindezi elizobhekana nazo ngesikhathi sokusebenza.

4. Imishini yokuhlola i-prototype:Imishini yokuhlola i-prototype efana nama-dynamometer nezinsimbi zokuhlola igiya ingasetshenziswa ukuhlola ukusebenza kwamagiya esibonelo futhi kuqinisekiswe ukusebenza kwawo. Lo mshini usiza ukuqinisekisa ukuthi amagiya ahlangabezana nezidingo zokusebenza ezifiselekayo ngaphambi kokukhiqiza ngokugcwele.

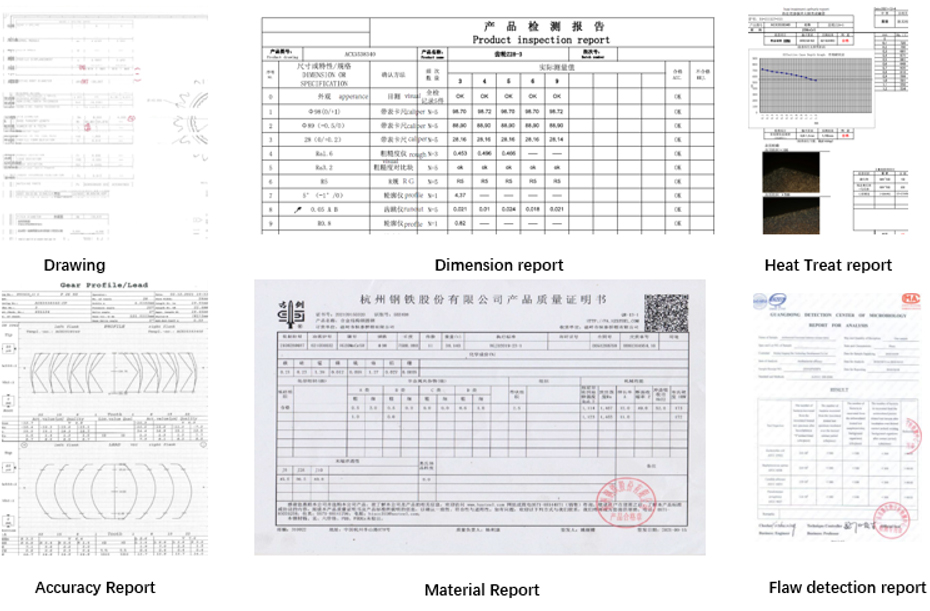

Ilebhu Yokuhlola Izinto

1. Ukuhlolwa kokubunjwa kwamakhemikhali kwezinto ezingavuthiwe

2. Ukuhlaziywa kwezakhiwo zemishini yezinto zokwakha

Izinto ezingavuthiwe ezihloselwe ukukhiqizwa kwamagiya ziyahlolwa ukuze kuqinisekiswe izakhiwo ezidingekayo, njengamandla, ukuqina, nokumelana nokugqoka, zihlangabezana namazinga adingekayo.

Izinto zokuhlola ezisetshenziswayo zingafaka:

I-High-precision Metallographic Microscopes ekhiqizwe yi-Olympus, Micro Hardness Tester, Spectrograph, Analytical Balance, Hardness Testers, Tensile Testing Machines, Impact Testers kanye ne-End Quenching Tester njll.

Ukuhlolwa kobukhulu

Ukuhlola kufaka phakathi ukukala iphrofayili engaphezulu kanye nokuqina, ibanga lekhoni elingemuva, ukukhululeka kwethiphu, ukuphuma komugqa we-pitch, namanye amapharamitha amagiya abalulekile.

I-German Mahr High Precision Roughness Contour Integrated Machine.

I-Swedish Hexagon Coordinate Measuring Machine.

I-German Mahr Cylindricity Measument Instrument.

Umshini Wokulinganisa we-ZEISS waseJalimane.

Ithuluzi Lokulinganisa Igiya le-Klingberg yaseJalimane(P100/P65).

Ithuluzi Lokulinganisa Iphrofayela ye-Mahr yaseJalimane njll.

Isithembiso Sethu

Sithemba ngobuqotho ukuthi amakhasimende ethu azokwaneliseka ngemikhiqizo yethu. I-Michigan Gears ithembisa ngokuzithoba ukuhlinzeka ngewaranti yonyaka owodwa kuyo yonke imikhiqizo uma ukonakala kungahambisani nemidwebo. Ikhasimende linelungelo lokucela izinketho ezilandelayo.

1. Ukubuyisela Nokuhwebelana

2. Lungisa umkhiqizo

3. Ukubuyiselwa kwentengo yoqobo yomkhiqizo onesici.