I-scanning electron microscope yasetshenziselwa ukubuka ukuphuka kokukhathala nokuhlaziya indlela yokuphuka; ngasikhathi sinye, ukuhlolwa kokukhathala kokugoba kwe-spin kwenziwa ezifanekisweni ezenziwe nge-decarburized emazingeni okushisa ahlukene ukuze kuqhathaniswe impilo yokukhathala yensimbi yokuhlola ne-decarburization nangaphandle, kanye nokuhlaziya umphumela wokukhipha inkabu ekusebenzeni kokukhathala kwensimbi yokuhlola. Imiphumela ikhombisa ukuthi, ngenxa yokuba khona kanye kanye kwe-oxidation kanye ne-decarburization enqubweni yokushisisa, ukusebenzisana phakathi kwakho kokubili, okuholela ekugqineni kongqimba olukhishwe ngokuphelele ngokukhula kwezinga lokushisa kukhombisa ukuthambekela kokukhula bese kuncipha, Ugqinsi lwesendlalelo esikhishwe ngokuphelele kufinyelela ku-120 μm ku-750 ℃, futhi ukujiya kongqimba olukhishwe ngokuphelele kufinyelela inani eliphansi lama-20 μm ku-850 ℃, futhi umkhawulo wokukhathala wensimbi yokuhlola ucishe ube ngu-760 MPa, futhi umthombo wokuqhekeka kokukhathala ensimbi yokuhlola ikakhulukazi i-Al2O3 inclusions non-metallic; Ukuziphatha kwe-decarburization kunciphisa kakhulu impilo yokukhathala yensimbi yokuhlola, kuthinta ukusebenza kokukhathala kwensimbi yokuhlola, ungqimba lwe-decarburization lushubile, impilo yokukhathala iyancipha. Ukuze kwehliswe umthelela wesendlalelo se-decarburization ekusebenzeni kokukhathala kwensimbi yokuhlola, izinga lokushisa elilungile lokwelashwa kwensimbi yokuhlola kufanele lisethwe ku-850℃.

Igiya liyingxenye ebalulekile yemoto, ngenxa yokusebenza ngesivinini esikhulu, ingxenye ye-meshing yendawo yegiya kufanele ibe namandla aphezulu kanye nokumelana nokuhuzuka, futhi impande yezinyo kufanele ibe nokusebenza kahle kokukhathala kokugoba ngenxa yomthwalo ophindaphindiwe oqhubekayo, ukuze kugwenywe imifantu eholela ezintweni ezibonakalayo. ukuphuka. Ucwaningo lukhombisa ukuthi ukususwa kwe-carburization kuyisici esibalulekile esithinta ukusebenza kokukhathala kokugoba kwezinto zensimbi, futhi ukusebenza kokukhathala kokugoba kuyinkomba ebalulekile yekhwalithi yomkhiqizo, ngakho-ke kuyadingeka ukuthi utadishe indlela yokukhishwa kwe-carburization nokusebenza kokukhathala kokugoba kwezinto zokuhlola.

Kuleli phepha, isithando somlilo sokushisa ekuhlolweni kwe-20CrMnTi gear steel surface decarburization, sihlaziye amazinga okushisa ahlukene okushisa okujulile kongqimba lwensimbi yokuhlola ukujula komthetho oguqukayo; kusetshenziswa umshini wokuhlola ukukhathala we-QBWP-6000J olula wensimbi ekuhlolweni kokukhathala kokugoba kwensimbi yokuhlola, ukunqunywa kokusebenza kokukhathala kwensimbi yokuhlola, futhi ngesikhathi esifanayo ukuhlaziya umthelela we-decarburization ekusebenzeni kokukhathala kwensimbi yokuhlola ukuze ukukhiqizwa kwangempela kuthuthukiswe. inqubo yokukhiqiza, ithuthukisa ikhwalithi yemikhiqizo futhi inikeze ireferensi enengqondo. Ukusebenza kokukhathala kwensimbi yokuhlola kunqunywa umshini wokuhlola ukukhathala ogobayo.

1. Izinto zokuhlola nezindlela

Izinto zokuhlola zeyunithi ezohlinzeka ngensimbi yegiya engu-20CrMnTi, ukwakheka kwamakhemikhali okuyinhloko njengoba kukhonjisiwe kuThebula 1. Ukuhlolwa kwe-Decarburization: impahla yokuhlola icutshungulwa ibe isifanekiso esiyisilinda esingu-Ф8 mm × 12 mm, indawo engaphezulu kufanele ikhanye ngaphandle kwamabala. Isithando somlilo sokushisa sasishisiswe sibe ngu-675 ℃, 700 ℃, 725 ℃, 750 ℃, 800 ℃, 850 ℃, 900 ℃, 950 ℃, 1,000 ℃, futhi sibambele ekamelweni lokushisa. Ngemuva kokwelashwa kokushisa kwesifanekiso ngokusetha, ukugaywa nokupholishwa, ngokuguguleka kwesisombululo se-nitric acid ye-nitric acid, ukusetshenziswa kwe-metallurgical microscopy ukuze kubhekwe ungqimba lwe-steel decarburization, ukulinganisa ukujula kongqimba lwe-decarburization emazingeni okushisa ahlukene. Ukuhlolwa kokukhathala kokugoba kwe-Spin: izinto zokuhlola ngokuya ngezidingo zokucutshungulwa kwamaqembu amabili amasampula wokukhathala okugoba, iqembu lokuqala alilwenzi ukuhlolwa kwe-decarburization, iqembu lesibili lokuhlolwa kwe-decarburization emazingeni okushisa ahlukene. Kusetshenziswa umshini wokuhlola ukukhathala ogoba i-spin, amaqembu amabili ensimbi yokuhlola ukuhlola ukukhathala okugobayo, ukunqunywa komkhawulo wokukhathala wamaqembu amabili ensimbi yokuhlola, ukuqhathanisa ukuphila kokukhathala kwamaqembu amabili ensimbi yokuhlola, ukusetshenziswa kokuskena. ukubona ukuphuka kokukhathala ngesibonakhulu se-electron, hlaziya izizathu zokuphuka kwesifanekiso, ukuze uhlole umphumela wokukhishwa kwe-carburization yezakhiwo zokukhathala zensimbi yokuhlola.

Ithebula 1 Ukwakheka kwamakhemikhali (ingxenye enkulu) yensimbi yokuhlola wt%

Umthelela wokushisa okushisa ku-decarburization

I-morphology yenhlangano ye-decarburization ngaphansi kwamazinga okushisa okushisa ahlukene iboniswa ku-Fig. 1. Njengoba kungabonwa emfanekisweni, lapho izinga lokushisa liyi-675 ℃, indawo yesampula ayiveli isendlalelo se-decarburization; lapho izinga lokushisa likhuphukela ku-700 ℃, ungqimba lwesampula lokususa umshini wokushisa umoya lwaqala ukuvela, ngongqimba oluncane lwe-ferrite decarburization; lapho izinga lokushisa likhuphuka liye ku-725 ℃, ukushuba kwesendlalelo se-decarburization yesampula kukhuphuke kakhulu; 750 ℃ ugqinsi lwe-decarburization layer lufinyelela inani eliphezulu, ngalesi sikhathi, okusanhlamvu kwe-ferrite kucace kakhudlwana, kumaholoholo; lapho izinga lokushisa likhuphukela ku-800 ℃, ugqinsi lwengqimba ye-decarburization lwaqala ukwehla kakhulu, ukushuba kwalo lwehla lwafika kuhhafu wama-750 ℃; lapho izinga lokushisa liqhubeka likhuphuka lifinyelele ku-850 ℃ futhi ukushuba kwe-decarburization kuboniswe ku-Fig. 1. 800 ℃, ugqinsi olugcwele lwengqimba ye-decarburization lwaqala ukwehla kakhulu, ukujiya kwalo lwawela ku-750 ℃ lapho isigamu; lapho izinga lokushisa liqhubeka nokukhuphuka lifinyelele ku-850 ℃ nangaphezulu, insimbi yokuhlola egcwele ungqimba lwe-decarburization iyaqhubeka nokuncipha, ukushuba kwengxenye ye-decarburization kwaqala ukwanda kancane kancane kuze kube yilapho i-morphology egcwele yengqimba ye-decarburization inyamalala yonke, i-decarburization layer morphology icace kancane kancane. Kungabonakala ukuthi ukushuba kwesendlalelo esikhishwe ngokuphelele ngokunyuka kwezinga lokushisa kwaqala kwandiswa futhi kwabe sekwehliswa, isizathu salesi simo sibangelwa isampula yenqubo yokushisa ngesikhathi esifanayo ukuziphatha kwe-oxidation kanye ne-decarburization, kuphela lapho izinga le-decarburization liyashesha kunejubane le-oxidation lizovela into ye-decarburization. Ekuqaleni kokushisisa, ukushuba kongqimba olukhishwe ngokuphelele umzimba bukhuphuka kancane kancane ngokukhuphuka kwezinga lokushisa kuze kube yilapho ubukhulu bengqimba eboshiwe ngokuphelele bufinyelela inani eliphakeme, ngalesi sikhathi ukuqhubeka nokukhulisa izinga lokushisa, isilinganiso se-oxidation yesampula siyashesha izinga le-decarburization, elivimbela ukwanda kwesendlalelo se-decarburized ngokugcwele, okuholela ekwehleni. Kungabonakala ukuthi, phakathi kwebanga elingu-675 ~950 ℃, inani logqinsi lwesendlalelo esikhishwe ngokuphelele ngo-750 ℃ likhulu kunawo wonke, futhi inani logqinsi longqimba olukhishwe ngokuphelele ngu-850 ℃ lincane kakhulu, Ngakho-ke, izinga lokushisa lokushisa kwensimbi yokuhlola linconywa ukuthi libe ngu-850 ℃.

Fig.1 Histomorphology of the decarburized layer of test steel egcinwe emazingeni okushisa ahlukene e-1h.

Uma kuqhathaniswa nesendlalelo se-semi-decarburized, ukujiya kwesendlalelo se-decarburized ngokugcwele kunomthelela omubi kakhulu ezintweni ezibonakalayo, kuzonciphisa kakhulu izakhiwo zemishini yezinto ezibonakalayo, njengokunciphisa amandla, ukuqina, ukumelana nokugqoka kanye nomkhawulo wokukhathala. , njll., futhi futhi ukwandisa ukuzwela emifantwini, okuthinta ikhwalithi ye-welding nokunye. Ngakho-ke, ukulawula ukushuba kongqimba olususwe ngokuphelele i-carburized kubaluleke kakhulu ukuthuthukisa ukusebenza komkhiqizo. Umfanekiso 2 ubonisa ijika eliguquguqukayo logqinsi lwesendlalelo esisuswe i-carburized ngokugcwele ngezinga lokushisa, okubonisa ukuhluka kogqinsi lwesendlalelo esikhishwe ngokuphelele. Kungabonakala kumfanekiso ukuthi ukujiya kongqimba olukhishwe ngokuphelele i-decarburized cishe ku-34μm kuphela ku-700℃; lapho izinga lokushisa likhuphuka lifinyelela ku-725 ℃, ukujiya kongqimba olukhishwe ngokuphelele umzimba bukhuphuka kakhulu bufinyelele ku-86 μm, okungaphezu kwezikhathi ezimbili zogqinsi lwengqimba ekhishwe ngokuphelele ngu-700 ℃; lapho izinga lokushisa liphakanyiselwa ku-750 ℃, ukushuba kongqimba olukhishwe ngokuphelele uma izinga lokushisa likhuphuka lifinyelela ku-750 ℃, ukushuba kongqimba olukhishwe ngokuphelele kufinyelela ku-120 μm; njengoba izinga lokushisa liqhubeka nokwenyuka, ukujiya kongqimba olukhishwe ngokuphelele umoya buqala ukuncipha kakhulu, bufike ku-70 μm ku-800℃, bese kuba buncane benani elingaba ngu-20μm ku-850℃.

Fig.2 Ukuqina kwesendlalelo esikhishwe ngokuphelele emazingeni okushisa ahlukene

Umthelela we-decarburization ekusebenzeni kokukhathala ekugobeni kwe-spin

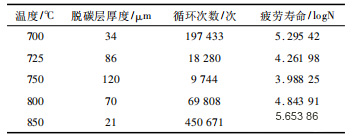

Ukuze kufundwe umphumela wokukhipha i-decarburization ezindaweni zokukhathala zensimbi yasentwasahlobo, kwenziwa amaqembu amabili okuhlolwa kokukhathala okugobayo, iqembu lokuqala laliwukuhlolwa kokukhathala ngokuqondile ngaphandle kokukhishwa kwe-decarburization, kanti iqembu lesibili laliwukuhlolwa kokukhathala ngemuva kokukhishwa kwe-carburization ekucindezelekeni okufanayo. izinga (810 MPa), kanye nenqubo yokususa i-carburization yabanjwa ku-700-850 ℃ ihora elingu-1. Iqembu lokuqala lama-specimens liboniswa kuThebula 2, okuwukuphila kokukhathala kwensimbi yasentwasahlobo.

Ukuphila kokukhathala kweqembu lokuqala lezibonelo kuboniswe kuThebula 2. Njengoba kungabonakala kuThebula 2, ngaphandle kwe-decarburization, insimbi yokuhlola yayingaphansi kwemijikelezo engu-107 kuphela ku-810 MPa, futhi akukho ukuphuka okwenzeka; lapho izinga lokucindezeleka lidlula i-830 MPa, ezinye zezibonelo zaqala ukuphuka; lapho izinga lokucindezeleka lidlula i-850 MPa, izibonelo zokukhathala zonke zaphuka.

Ithebula 2 Impilo yokukhathala ngaphansi kwamazinga ahlukene okucindezeleka (ngaphandle kwe-decarburization)

Ukuze unqume umkhawulo wokukhathala, indlela yeqembu isetshenziselwa ukunquma umkhawulo wokukhathala wensimbi yokuhlola, futhi ngemva kokuhlaziywa kwezibalo zedatha, umkhawulo wokukhathala wensimbi yokuhlola umayelana ne-760 MPa; ukuze kubonakale impilo yokukhathala kwensimbi yokuhlola ngaphansi kokucindezeleka okuhlukene, ijika le-SN lihlelwe, njengoba kuboniswe kuMfanekiso 3. Njengoba kungabonakala ku-Figure 3, amazinga ahlukene okucindezeleka ahambisana nempilo ehlukene yokukhathala, lapho impilo yokukhathala ye-7 , elihambisana nenani lemijikelezo engu-107, okusho ukuthi isifanekiso esingaphansi kwalezi zimo singohulumeni, inani lengcindezi elihambisanayo lingalinganiselwa njengenani lamandla okukhathala, okungukuthi, 760 MPa. Kungabonakala ukuthi ijika le-S - N libalulekile ekunqumeni impilo yokukhathala kwento enenani elibalulekile lokubhekisela.

Umfanekiso 3 Ijika le-SN lokuhlola ukukhathala okugobayo kwensimbi

Ukuphila kokukhathala kweqembu lesibili lezibonelo kukhonjisiwe kuThebula 3. Njengoba kungabonakala kuThebula 3, ngemva kokuba insimbi yokuhlola ikhishwe emazingeni okushisa ahlukene, inani lemijikelezo liyancipha ngokusobala, futhi lingaphezu kuka-107, futhi konke izibonelo zokukhathala ziphukile, futhi impilo yokukhathala iyancipha kakhulu. Kuhlanganiswe nogqinsi lwesendlalelo se-decarburized olungenhla nejika lokushintsha izinga lokushisa kungabonakala, ugqinsi lwengqimba ye-decarburized engu-750 ℃ lukhulu kakhulu, oluhambisana nenani eliphansi kakhulu lempilo yokukhathala. 850 ℃ ugqinsi lwengqimba ye-decarburized luncane kakhulu, oluhambisana nenani lempilo yokukhathala liphezulu uma kuqhathaniswa. Kungabonakala ukuthi ukuziphatha kwe-decarburization kunciphisa kakhulu ukusebenza kokukhathala kwento, futhi uma ungqimba owenziwe nge-decarburized lushubile, impilo yokukhathala iyancipha.

Ithebula 3 Impilo yokukhathala emazingeni okushisa ahlukene e-decarburization (560 MPa)

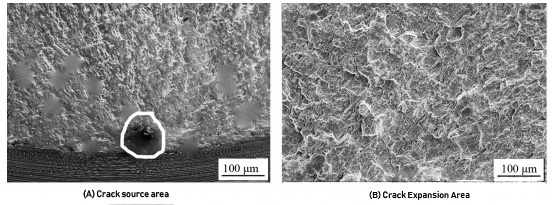

I-morphology yokuphuka kokukhathala kwesampula yabonwa ngokuskena isibonakhulu se-electron, njengoba kuboniswe kumfanekiso 4. Umfanekiso 4(a) wendawo yomthombo wokuqhekeka, isibalo singabonakala i-arc yokukhathala esobala, ngokusho kwe-arc yokukhathala ukuthola umthombo. ukukhathala, kungabonakala, umthombo crack for the "inhlanzi-iso" non-metallic inclusions, inclusions at the lula ukubangela ukuhlushwa ukucindezeleka, okuholela imifantu ukukhathala; Umdwebo 4(b) we-morphology yendawo yokwandisa i-crack, iyabonakala imivimbo yokukhathala esobala, kwakuwukusabalalisa okufana nomfula, okungokwehlukana kwe-quasi-dissociative, okunwebekayo, okuholela ekuqhekekeni. Umfanekiso wesi-4(b) ukhombisa ukumila kwendawo yokunwetshwa kwemifantu, ukukhathala okusobala kungabonakala, ngendlela yokusabalalisa okufana nomfula, okuyingxenye yokuqhekeka kwe-quasi-dissociative, kanye nokwanda okuqhubekayo kwemifantu, ekugcineni kuholele ekuqhekekeni. .

Ukuhlaziya ukuphuka kokukhathala

I-Fig.4 SEM morphology yokukhathala kokuphuka kwendawo yensimbi yokuhlola

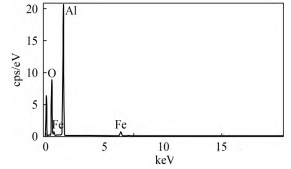

Ukuze unqume uhlobo lokufakwa ku-Fig. 4, ukuhlaziywa kwe-spectrum ye-spectrum yamandla kwenziwa, futhi imiphumela iboniswa ku-Fig. ziwumthombo oyinhloko wokuqhekeka okubangelwa ukuqhekeka kwe-inclusions.

Umfanekiso we-5 Energy Spectroscopy ye-Non-metallic Inclusions

Phetha

( 1) Ukubeka izinga lokushisa lokushisisa ku-850 ℃ kuzonciphisa ukujiya kongqimba lwe-decarburized ukunciphisa umthelela ekusebenzeni kokukhathala.

( 2) Umkhawulo wokukhathala we-test steel spin egoba yi-760 MPa.

( 3) Insimbi yokuhlola iqhekeka ekufakweni okungezona ezensimbi, ikakhulukazi ingxube ye-Al2O3.

4

Isikhathi sokuthumela: Jun-21-2024